HIGH SPEED INFRARED CAMERAS (1 – 5 MICRONS)

TACHYON 16K +

High speed (>4,000 fps) uncooled Medium Wave Infrared (MWIR) Cameras for controlling and monitoring industrial processes.

Allows to implement artificial inteligence (AI) and algorithms to develop custom solutions.

Focus to improve quality and increase productivity in many industrial processes at affordable and competitive prices.

TACHYON 16k CAMERA

WAAM process monitoring

TACHYON 16k CAMERA

Powder Bed Fusion process monitoring

TACHYON 16k CAMERA

WAAM process monitoring

TACHYON 16k CAMERA

WAAM process monitoring

| MAIN SPECIFICATIONS |

| DETECTOR TYPE | VPD PbSe FPA with digital interface, uncooled operation |

| ARRAY FORMAT | 128×128 (16384 pixels) |

| PIXEL SIZE | 50 um x 50 um (square format) |

| SPECTRAL RANGE | MWIR, 1.0 µm to 5.0 µm |

| PEAK WAVELENGTH OF DETECTION | 3.7 microns |

| INTEGRATION TIME | 10 – 1000 µs, selectable |

| RAW DATA COMMUNICATION | 14 bit |

| INTERFACES | – GigE VISION 2.0 (GenICam compatible) with PoE – Multipurpose DI/DO connector (trigger IN/OUT) (cable sold separately) |

| MAXIMUM FRAME RATE | 4000 fps (TACHYON 16k CAMERA PLUS) (see table) |

| ROI | ROI windowing function (see table for full description of possible modes) |

| MECHANICAL SHUTTER | Mechanical shutter for 1-pt offset correction |

| START-UP TIME | < 10 seconds |

| POWER SUPPLY | PoE, 8 W (non-PoE operation requires 12 VDC) |

| Metal housing with rear connectors and tripod screw holes (M3 and M4) | |

| DIMENSIONS AND WEIGHT (W/O OPTICS) | 66 (L) x 62 (W) x 62 (H) (mm), 400 grams |

| OPTICS (STANDARD OPTION) | f=35 mm, F#1.1, FoV 10.5º x 10.5º, AR Coating (1 – 5 µm) Manual focus with CS-mount interface |

| SOFTWARE INCLUDED | – NIT SOFTWARE SUITE (Acquisition and visualization SW) – SDK available for custom software programming |

| MINIMUM TEMPERATURE OF DETECTION | 100 ºC |

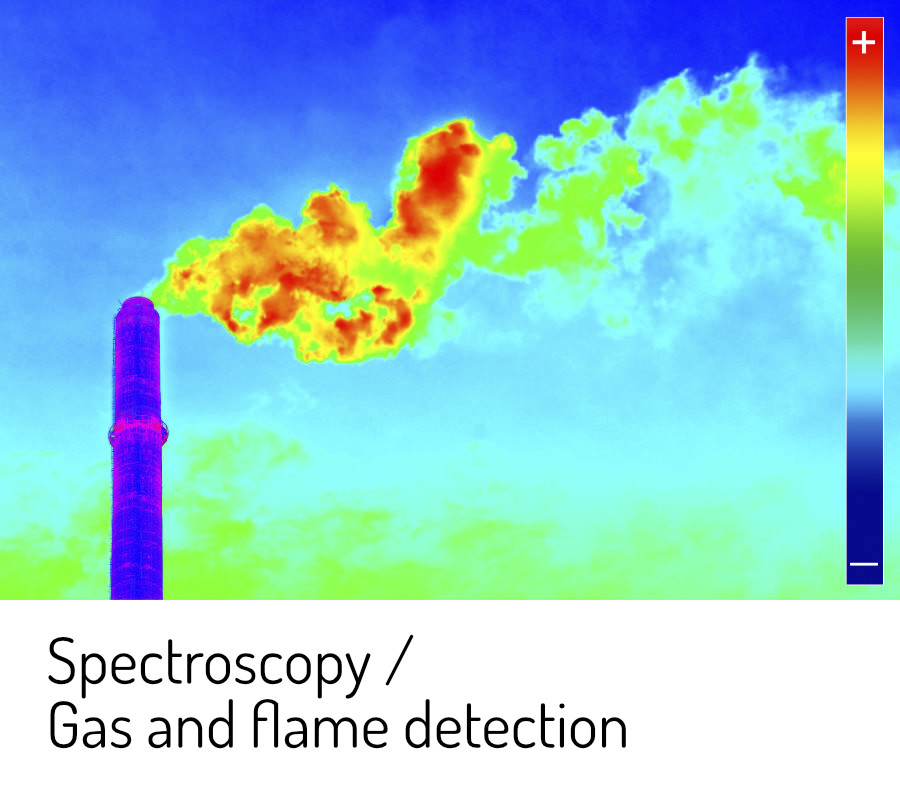

| INDUSTRIAL APPLICATIONS | Machine vision, additive manufacturing, industrial process monitoring, gas detection, spectroscopy, glass manufacturing quality assurance |

| DIFFERENCES BETWEEN TACHYON 16K AND TACHYON 16K PLUS |

| TACHYON 16K | TACHYON 16K PLUS |

| TACHYON 16K | TACHYON 16K PLUS | |

| MAXIMUM FRAME RATE | 2000 frames per second @ 128 x 128 | 4000 frames per second @ 128 x 128 Allows higher frame rates using embedded ROI windowing functions |

| ACQUISITION MODE | 128 x 128: Interlaces acquisition 64 x 64, 32 x 32, 1 x 128: Global shutter acquisition | All modes: Global shutter acquisition |

| WINDOWING MODES | 128×128 64×64 (center of FPA) 32×32 (center of FPA) 1×128 (center of FPA) | Window position and dimensions: configurable via SW |

| NUC CORRECTION TABLES | Software correction | Hardware correction (4 preconfigured tables) |

| DATA TRANSMISSION MODES | RAW data, 14 bit | Selectable: – RAW data, 14 bit – NUC corrected, 16 bit – High-speed mode RAW/NUC: 12 bit |

10 seconds

10 seconds